Bedside Fall Safety Mats

Fall Protection Safety: How to Choose the Best Fall Protection Equipment

As occupational hazards go, falling ranks among the top causes of injury and death on the worksite, making finding the right fall protection equipment essential for safety. Responsible for one out of every seven workplace fatalities in the US, falling from distance is a dangerous occurrence that can ultimately be prevented with some foresight and proper planning as well as the right equipment. Fall protection equipment is rapidly becoming federally mandated by OSHA for all worksites, big and small, and it is important to note the many different devices and kits on the market made to ensure federal compliance.

The basic components of the ANSI or OSHA mandated fall protection equipment consist of three different categories: harnesses, connection lanyards or "lifelines", and anchors or "tie-offs." The combination of these three components together comprises the heart of a fall protection system. There are many options for each category, but all three must be used in conjunction with each other; without one of these three devices, the other two will not provide protection from falling, so be sure to have these bases covered first and foremost. We"ll start with a quick overview of each main component of a complete fall protection system, before detailing the many options available for each device. Later on we will touch on the options and accessories that can be added to the basic fall protection system to provide increased protection and support, as well as some of the full kits available to help you comply with the federal mandates.

To begin to detail the finer points of fall protection, let us first look at the worker who will be using the system. In order to safely prevent injury, a worker must have a way to secure themselves to the fall protection system. This is where harnesses come into play. There are many different harnesses available for a number of different weights, heights and specific worksites, and fitting the harness correctly to each worker is very important to ensure and insure safety. Typically harnesses are manufactured in multiple sizes, ranging from small adult to XXL. Other harnesses are designed to be what the manufacturers call a "universal fit." These harnesses are adjustable for a wide range of sizes, and come in a variety of styles which we will touch on later on in this article. By providing a point of connection to the environment, the harness protects and provides support to the most important factor in fall protection, the worker.

Once there is a point of connection on the user, the next step is making the connection to the structure. This is where connection devices such as lanyards and lifelines come into play. Designed to live up to their names, lifelines provide the actual protection from injury during a fall. This is perhaps the most varied category of fall protection devices, as there are hundreds of styles and features for a variety of professions. Shock-absorbing lanyards are most popular, they are simple devices made to decrease the distance of a fall if it occurs as well as decrease the force exerted on the worker during a fall. Typically manufactured in 3" and 6" lengths, and used where fall clearance is not an issue, these lanyards limit the damage from a fall by providing the wearer with a somewhat cushioned impact. Personal fall limiters and self-retracting lifelines are other types of lifeline that can vary in design, but ultimately provide the same protection. Designed for places where a fall must be of a limited distance, fall limiters and self-retracting lifelines (SRLs) are pulley systems that work very similar to seat belts in motor vehicles. When SRLs are pulled on rapidly, like during a fall, the pulley in the devices will lock, preventing the line from expanding any further. This not only helps to limit the shock and injury of falls, but decreases the amount of distance the crews must travel to reach the fallen worker. SRLs are typically built with tough and durable materials that can be used for years without issue and they are federally mandated at some jobsites due to their ease of use and their proven reliability for limiting fall distance. Lifelines, lanyards and SRLs are the bridge between the user and the structure or environment and must be carefully and thoughtfully considered when building a personal fall protection system.

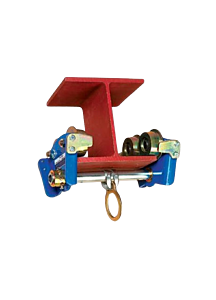

Anchors are the final piece to the fall protection puzzle, they can range from simple locking bolt connectors on an I-beam, to full anchorage rigs for multiple workers working off the side of a building safely. The type of anchor used to complete a fall protection system is heavily reliant on the type of workplace, the environment where it will be installed. There are as many different anchors as there are jobsites, so it is very important to know and understand just where and how the device will be used before completing your fall protection system. Anchors must be dutifully checked to ensure the weight of the worker will be well-supported if a fall were to occur. Federal requirements state that any anchor must be able to hold a minimum of 5000lbs. and must match the environment where it is being used. Roof anchors are specifically designed for locking the user to the most structurally sound part of the roof, metal anchors to the most structurally sound part of the tower or building. Each and every jobsite where fall protection is necessary, a specific anchor must be used. Determining your needs and your environment will allow you to decide the best suited anchor for you and your workers.

Federally approved fall protection must consist of these three components: Harnesses, lifelines and anchors. A complete fall protection system cannot exist without any one of these parts. In order to help define and provide an overview of the many examples of each piece of equipment, the following information will consist of different options, details and features for each of the three main components of a complete fall protection system, followed by the many complete kits available for complete federal fall protection compliance.

Fall Protection Harnesses

As of the first of January 1998, federal regulations mandated that all fall protection harnesses must be full body harnesses. Body belts that were used prior to this date were found to be unsupportive of the neck and back and insufficient for the protection described in ANSI and OSHA guidelines. Since that date, many different full body harnesses have been developed to support the wearer, not only during a fall, but throughout the workday. Options like the DBI/SALA Full Body Vest Style Harness are universal fit harnesses, designed to spread the user"s weight across the body when suspended to create a feeling of comfort and support. The nylon straps fit around the back and pelvis and are adjusted with buckles to prevent slippage, a design that centers the weight slightly below the neck to limit the force on the spine in case of a fall. This is the classic and most popular style of harness available, it can be utilized in a variety of worksites and environments to ensure the workers" safety at all times. Worksite specific harnesses are also available, like the Miller Non-Stretch Harness. This harness is constructed of a reinforced strapping material and is designed for general construction environments, contracting and scaffolding. Designed to accommodate tool belts, fit a wide range of users, and still provide the necessary support and protection mandated by Federal guidelines, this harness is a perfect solution for construction site compliance. Another workplace specific harness is the DBI/SALA Medium ExoFit Derrick Harness designed for workers in the oil rig industry. These ExoFit Harnesses are built with an 18" extension D-ring for extra security, and extra padding for the hips, waist and back. The vest style harness design features a sling seat for comfort when suspended for long periods of time, perfect for the extended shifts oil workers typically maintain. With positioning D-rings on the back and sides, these harnesses are made for safe repositioning across horizontal fixtures found specifically on oil rigs, and the leg straps and shoulder buckles are adjustable to custom fit to a variety of oil workers. By designing these harnesses specifically to the jobsites, harness manufacturers make the process of ensuring federal compliance, and ensuring the safety of the workers who wear the harnesses, very simple and straight-forward, if you know the job, you know the harness.

Fall Protection Lanyards, Rope, and Cable

Identifying the best suited harness is as simple as knowing what jobsite the fall protection is needed for, similarly, identifying the best connecting device necessary for compliance is simple as well. Self-retracting Lifelines and lanyards are connecting devices responsible for the connection between the worker and the worksite and are very important factors in fall protection. Different connection devices are designed with the various federal OSHA and ANSI guidelines in mind, and when paired with the appropriate anchor and harness, complying with those guidelines is quite simple. Depending on the distance between the worker wearing the device, the structure below, and the federally mandated fall distance minimums, selecting an appropriate device for your worksite is based on simple math. If the fall clearance is greater than 18½ ft., shock absorbing lanyards, fall limiters and self-retracting lifelines are best suited, however if the fall distance is less than 18½ ft., only a self-retracting lifeline can be used, and only SRLs with proper certification for the specific clearance minimum. Much like the harnesses, SRLs are designed for different applications and are regulated by the specific federal worksite guidelines. Retractable lifelines and SRLs like the DBI/SALA Rebel SRL 11" Lifeline are becoming more and more popular in worksites as the need to switch-out equipment for different fall clearances can be avoided entirely with these devices. The Rebel is extremely strong and has the best weight-to-length ratio in the industry. The unique super-strength webbing and lightweight design make for amazing portability, making it a perfect match for construction sites where fall clearance is limited. When the fall distance is greater than 18½ ft., lanyards like the Miller 6" Stretchstop ™ Lanyard are preferred, as they stretch when a fall occurs which reduces the impact of the fall, providing comfort as well as protection. Not only do specific lanyards and SRLs need to be used for the specific jobsite, the jobsite itself determines the application of these devices. For worksites where a standard SRL or lanyard cannot be used, or where the workers must work across a horizontal distance, Horizontal Lifeline Systems like the Miller SkyGrip 4 Person Temporary Horizontal Lifeline are used. Tremendously effective for bridge work, building maintenance, or painting, these devices allow one or more workers to safely across a distance without having to repeatedly change out equipment or disconnect from the lifeline. The worker continues to wear their SRL or lanyard, but can move much greater distances across the site. A safe and secure alternative to standard lifeline systems, these horizontal lifelines are amazingly convenient additions to any suitable jobsite. By addressing the variety of circumstances where an SRL, shock-absorbing lanyard, or horizontal lifeline is necessary, you narrow down the options available and provide yourself with the best solution for fall protection and federal compliance at your worksite.

Fall Protection Anchors

Harnesses and Connection Devices build the framework for reliable fall protection, however the third factor, the anchorage connection may be the most important. Proper anchorage must support a mandated 5000 pound minimum in order to meet federal guidelines and ensure the safety of the workers using it. Anchors must be continually inspected to ensure they are in proper working order, and there are federal regulations regarding the discontinued usage of anchorage devices once they are involved in a fall arrest. This limits the places where an anchor can be utilized on the jobsite, as well as what type of anchor can be used. Much like the harnesses and connection devices, the other two major components of a complete fall protection system, the anchor must be matched to the jobsite where it is being used. Beam or flanged anchors are used in construction sites and high-rises, work environments where the worker is positioned near or on top of the same beam they are anchored to, and are available in either fixed or adjustable lengths. Anchors like the Miller Shadowlite Beam Anchor are adjustable for a variety of different beams, the ratcheting design allows the user to work freely in multiple scenarios with confidence and security. Beam anchorage devices carry many regulations for their safe application; they cannot be installed on open ended beams, or on vertical beams, in order to prevent an increase in the potential fall distance. For workers on concrete construction sites, wedge anchors are typically use to anchor the worker on a vertical face. An example of a popular reusable wedge anchor is the DBI/SALA SafLok Concrete Wedge Anchor, designed to be installed temporarily into the outer face of a concrete structure and be easily removed and reused. These are remarkable anchorage points as they virtually eliminate the need for concrete anchor removal tools, freeing the user up to work more efficiently without sacrificing safety. Multipurpose anchors are also available, like the DBI/SALA Pass-Thru Tie-Off Adapter Anchorage Connector , designed to be used around beams and other structurally sound points. Constructed of an extremely durable 5,000lb tensile strength polyester fabric, the simple pass-through design allows the anchor to be placed almost anywhere a secure anchorage point is needed, and can be easily removed and repositioned. Perhaps the most important safety step to prevent a dangerous fall, secure anchorage will save lives and must be thoughtfully researched before equipped.

The federal requirements for fall protection are very insistent and strict, and they set forth requirements that are sometimes hard to fulfill. OSHA and ANSI were established to protect the worker, and their dedication to developing these comprehensive guidelines for safety do save lives. Without these regulatory boards, many workers would be at high risk of serious injury or death. Complying with these guidelines can be difficult, as each worksite can contain a variety of devices necessary for fall protection as we have already discussed. In order to simplify this necessity, many companies have begun to develop packages that contain everything a worker would need to comply with federally regulated mandates. Convenient and comprehensive, these kits are available in worksite specific options, containing everything necessary for the specific job. The Miller Basic Roofing Kit for example includes all the parts a worker needs to become federally compliant and protected from a fall off a roof all in one bucket. Concrete worker kits, tower worker kits, horizontal lifeline kits, no matter the job, there are complete options available to help you become federally compliant and safe around the worksite.

Due to the severity and commonality of injuries from falls, Federal fall protection compliance cannot be ignored. OSHA and ANSI mandates were initiated to help protect construction workers and contractors, and because safety is of an utmost concern, the fines and penalties for non-compliance are incredibly steep. By purchasing and installing federally approved equipment from ActiveForever.com, you are not only protecting the workers, but are protecting yourself. With simple pre-planning and some help from us, complete fall protection and prevention is an attainable goal. Buy your fall protection devices today and take a step to a safer tomorrow!